Floating shelves are an easy and on-trend way to add storage and flair to any space. But how much weight can a floating shelf hold?

TLDR: A floating shelf can hold 45-50 pounds for every wall stud that your floating shelf bracket is attached to. For instance, a 3’ shelf that’s attached to two wall studs can safely support ~100 pounds. Likewise, a 2’ shelf bracket attached to two wall studs can easily support the same ~100 pounds. For the majority of use-cases and scenarios, the most important factor is how many wall studs your floating shelf bracket is fastened to. There are, of course, other factors to consider…

The Longer (and More Complete!) Answer:

Long before you start drilling holes in your wall, take a second and think about what you actually need. This kind of goes without saying, but like my grandpa always said, if you don’t know where you are going, you’ll get nowhere fast.

First, you need to know approximately how much weight you need to support on the shelf. Second, determine the width x length that the shelf needs to be to get everything onto it comfortably. Have a basic idea of where you need to go, then you can adjust the various factors to meet the needs of your project.

A properly installed heavy-duty floating shelf can support anywhere from 25lbs to well over 300lbs. That's a big range. How much weight a floating shelf can hold is really dependent on a number of factors, including:

- Where and how the floating shelf and floating shelf bracket will be installed.

- Quality & design of the shelf itself as well as the underlying floating shelf bracket.

- The desired length and depth of your floating shelf or floating mantel.

For your particular shelf or shelves, digest the following principles and then shop and install accordingly:

Location, Location, Location: Where (and How!) You Install Your Floating Shelves is Key

Floating shelves can only hold high weight capacities when attached to something solid like wall studs or masonry block. A Floating Shelf can hold even more weight when it's secured into something solid all the way across the length of the shelf. If there are gaps where the bracket is not fastened to something solid, flex and sag can occur.

No matter how gnarly the floating shelf bracket, in the end, floating shelf weight capacity is still 45 to 50lbs per stud that the bracket is attached to. READ: more screws attached to more wall studs (or blocking!) means higher weight capacity for your floating shelves. Period. Trying to fasten a heavy-duty floating shelf bracket into drywall only is a bad idea. And you can forget about trying to store anything beefy on it. Ain’t gonna happen.

How to Find Wall Studs

Finding wall studs isn’t rocket science. In most cases, wall studs are usually 16″ apart (24″ in some older homes). So that is a good assumption to start with. But honestly, the location of the studs can vary wildly depending on the age of your home and/or building codes in your area. Often, finding studs is a game of trial and error. But before you go punching holes in the wall, there are some easy hacks for finding the studs.

First, the easiest and honestly most effective way is to buy a stud finder. Done and dusted! Alternatively, you could go old school and just use “the knock test”: gently knock on the wall listening for a change in density. Start at light switches, outlets, or electrical boxes: they are typically installed on a stud. Also, there are studs on either side of most windows. Another trusty method is to measure 16 inches from a corner and start knocking. If you need help, feel free to call one of our friendly installation support monkeys and they can try to walk you through it over the phone.

Wanna hold up even more weight on your floating shelf? Install your shelf into solid blocking! Most homes in the US are stick frame construction. So dollars to donuts your house has wood studs framing the walls. The problem with installing floating shelves on this type of wall is that the wall studs are spaced every 16” apart. Floating shelves mounted into these periodic studs will be plenty strong. But... they won’t be as strong as floating shelves mounted into a solid backing that runs along the entire length of the shelf. The gaps between mounting points could introduce flex in the bracket. Best-case scenario, the shelf will be weaker. Worst case, the shelf can start to sag.

In the above illustration, imagine that the blocking is removed and the middle rod of the floating shelf bracket is not attached to anything behind it. Without that attachment, the rod can be bent downward much easier. This equates to lower floating shelf weight capacity and possibly shelf sag. To avoid sagging or weenie shelf capacity, attach the entire bracket to something solid, ideally blocking, like in the illustration.

Quality & Design: When Weight Matters, Only Settle for the Best Materials

If you want your floating shelf to support gnarly weight, you are gonna need an equally gnarly floating shelf bracket. Apart from location and proper installation, choosing a quality floating shelf bracket is the most important factor when shelf capacity is a concern. So choose carefully! For instance, our Aksel line of floating shelf brackets features beefy 1/4” thick solid-steel construction. Its shelf support rods are recessed into the backbar and 360 degree welded on the rear of the bracket (rather than front-facing welding which would further undermine the integrity of the construction). Good luck getting one of these puppies to sag or bend! Don’t be fooled by our wack imitators. Only settle for a tried and true heavy-duty bracket if you want to build floating shelves that will stand the test of time.

Floating Shelf Length & Depth Determine Weight Capacity

Absorb this principle: DEEPER IS NOT ALWAYS BETTER. In fact, generally speaking, the deeper your floating shelf, the less weight it can hold (or the stronger the floating shelf bracket needs to be). Simple physics dictates that the longer the lever, the less force it takes to move it. So… If your floating shelf is the lever and it gets longer (deeper), then less weight is required before it starts to sag. The takeaway: only use a floating shelf that is as deep as you need. If you go deeper than necessary, you will lose weight capacity. For example, if you are floating a bookshelf, typically your shelf shouldn’t need to be deeper than 10" since most books are less than 9" deep. Alternatively, if you are floating kitchen shelves, 12" usually works since kitchen cabinets and the plates, cups, and bowls they house are typically 12" deep or less.

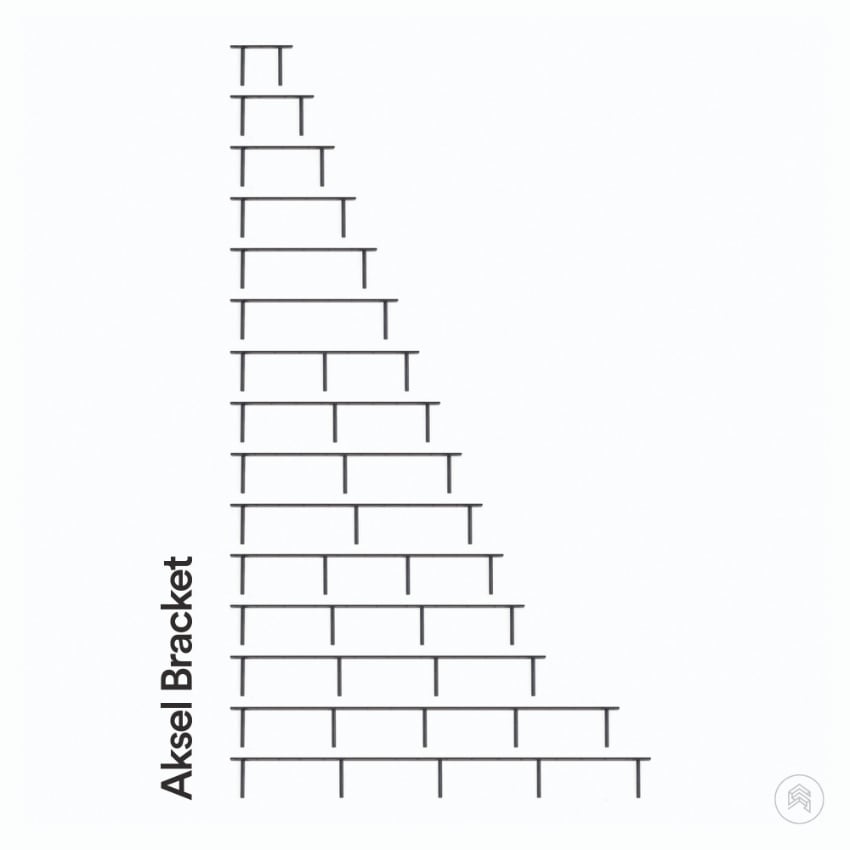

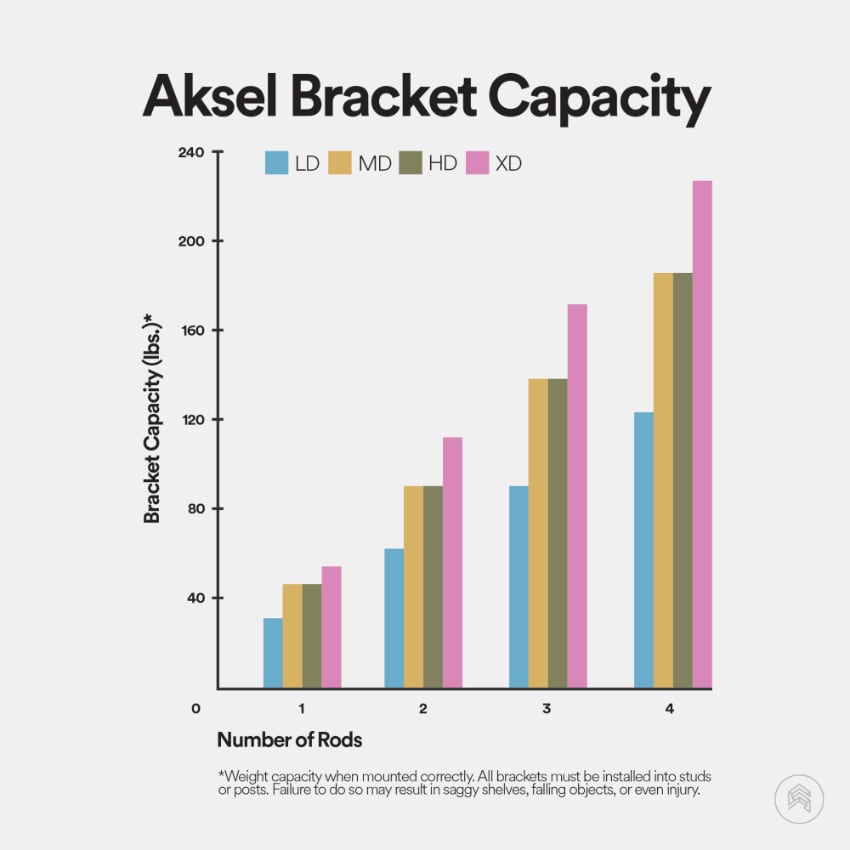

Another principle to remember is that more rods in your floating shelf bracket = greater floating shelf weight capacity. Pick a bracket that has enough horizontal rods welded onto it to adequately support your shelf. This is where knowing how much weight capacity you need comes in. Each support rod will carry a certain amount of weight on its own, and together those capacities add up to the bracket's total capacity.

For example, a Shelfology 34" heavy-duty floating shelf bracket has three rods welded to it. Each rod can individually handle roughly 45-50 lbs. Collectively, however, they add up to upwards of 135 pounds of total bracket capacity. For shelves longer than 36" be sure that the bracket you choose has additional rods as your shelf gets longer. Over 50" we recommend at least four rods in the bracket, over 70" we recommend at least five rods.

If you need a short shelf that needs to hold more weight than the two rods a standard floating shelf bracket has, no problem! Contact us about creating a custom bracket with additional rods. Or you could buy multiple shorter brackets to get the same effect without welding. For example, if you have a 30" shelf that needs exceptional weight capacity, you can either customize a standard Shelfology 26" floating shelf bracket with two additional rods, or you can use two 10" floating shelf brackets, with two rods each on them. The effect is the same. Four rods of support inside your 30" floating shelf.

So there you have it. Properly planned and installed heavy-duty floating shelves can hold a ton (see what I did there?!). Need help choosing the perfect floating shelves or floating shelf bracket? We’re here to help. Our cadre of shelf nerds can help you pick out the perfect custom shelf for any space in your house.